why e-mobility is moving towards a full DC charging ecosystem

In business, it takes courage to do something new. This may seem obvious, but there are countless stories of companies who have waited for the mass adoption of new technology even when the business advantages, and user benefits to be gained are obvious. Apple’s recent move toward technological[L1] progress is a prime example. Not only did they make the CD drive and Ethernet port on laptops outdated, they removed the century-old headphone jack. Phil Schiller, Apple’s marketing chief, explained the decision in one word – courage. In fact, he did not even try to convince users of the benefits. When he spoke to the media he said, “they might not understand it now, but one day they will”. Now, a few years down the road, the removal of the headphone jack was the start of a new level of convenience and simplicity. One day, a similar story will be told about the demise of AC chargers.

The inconvenient truth is DC charging is the way of the future, and there is significant evidence to support this. First, battery capacity has increased to a size where on-board chargers (OBC) are no longer required. It is now possible for EV owners to drive at least 200 miles on a full charge[1] and research shows a single day’s commute only averages 40 miles[2]. That means, it is now possible for EV owners to drive for days before the battery runs out. This is supported by Global EV Outlook who acknowledged that the average EV battery capacity has increased from 20-30kWh in 2012 to 70-80kWh in 20183.

On top of that, public DC charging networks are rapidly growing because of the anticipated rise in EV sales. The Edison Electric Institute projects that the next 1 million EVs will be on the road by early 2021, and the total number of EVs on the road will reach more than 18 million in 2030[3]. To accommodate for this growth, IONITY, a joint venture by four major car manufacturers, is building a network of 400 high-power DC chargers that has the ability to recharge a battery in an estimated 10 minutes.

As EV battery capacity and charging networks continue to grow, three scenarios are expected to take shape to form a DC only charging environment.

- Private charging at home which includes the utilisation of the EV’s battery as a general energy storage element

- Public charging to enable long-distance driving

- Maximising unused energy during fleet downtime

Private DC charging at home

Contrary to popular belief, EV charging takes less time to charge than pumping petrol. That is because, EV charging can take advantage of the time that vehicles are parked, which according to Fortune is estimated to be 95% of the time[4]. So, even though EV charging takes longer than pumping petrol, EV charging can take place when the owner is not actively attending to the car – while sleeping, eating, shopping, or working. If you factor in the time it takes to drive to a station to pump petrol, EV charging at home can actually save time. The same can be said of charging at work, if it is available.

However, with the increase in charging in general, it is not possible for the existing grid infrastructure to support the growing load, particularly at peak electricity usage hours. To address this challenge, some companies, like Rectifier Technologies, an Australian company that specialises in developing and manufacturing high efficiency power conversion products, are integrating bi-directional capabilities with their DC chargers to create a sustainable charging environment. This will allow electricity from the EV battery to be returned to the grid when needed (V2G) and with careful control, power can be exported to homes so EV charging can be efficiently balanced throughout a 24-hour period.

Public DC charging for long-distance driving

Once upon a time, people laughed at the idea that an electric vehicle could be used for day-to-day travel, let alone used for long-distance road trips. Fast forward to today and High-Power Charging units (HPC) now give EVs bursts of power along highways. During a short break to eat, rest, or stretch legs, this technology can offer a charging power of 150kW to 350kW and higher output power is in discussion for electric trucks.

Along with the growing number of DC fast chargers (~50kW) installed at various destinations, long trips in an EV are becoming increasingly practical. In the US, Green Car Congress[5] reports over 10,860 DC fast charging units and as this number continues to increase globally, EVs will continue to evolve from an alternative, to a preferred mode of transportation.

Maximising unused energy during fleet downtime

Whether it be hauling freight, delivering goods, or moving people, fleet EVs is playing a critical role in transforming industries and lowering costs. They do so by reducing the need for petrol and minimising the amount of maintenance on combustion engines. This of course, meets the needs of today’s consumers who value companies who embrace sustainable initiatives.

Fleet EVs also present an untapped opportunity to maximise battery capacity during downtime. If a fleet of 10 buses (which has at least 300kWh battery) can export just 5% energy during their down time, that’s 150kWh– the equivalent to the entire battery capacity of at least 2 long-range passenger vehicles. Now picture this when the number of electric bus increases to its expected 3.2 million by 2025 according to Global EV Outlook. This does however require a high-power bi-directional charger which is not readily available in the market.

The result? AC chargers are becoming redundant

As the growth of DC public charging infrastructure continues, and at-home DC charging becomes more common, car manufacturers will no longer have any reason to provide bulky OBCs. This will pave the way for lower manufacturing and material costs due to the more simplified and lighter vehicle architecture. Like the headphone jack, premium EV real estate can be saved for additional technology, or even larger battery capacities.

The irony is, even though it makes sense to switch to DC charging, the adoption of DC chargers is held back by incumbent stakeholders. While the removal of OBCs is occurring in some fleet vehicles in an effort to reduce overheads, the transition to every-day vehicles is stalled because alike any type of change, there is a misconception that we need the very thing we are trying to give up.

Two causes for resistance. One is that a lot of time and money has been spent on private and public AC charging infrastructure. Because of this, many industry stakeholders are trying to persevere despite evidence of the contrary.

The other concern has to do with the unlikely event of an EV battery running flat with no nearby DC charger available. The misconception that the only way to overcome this is to include an OBC in EVs is simply not true. An inexpensive portable DC charger of no more than 3kW of power that plugs into any general power outlet, settles this easily.

As we move towards a better reality, it is understandable to detach from AC charging bit-by-bit. But if there is a lesson to be learned from Apple it is that slow change breeds resistance. If we can take EV buyers to the promised land quicker, it reduces the complexity of change and minimises loss aversion. All the industry is waiting for is for one car manufacturer to be the first mover in leading this change.

The Rectifier differences

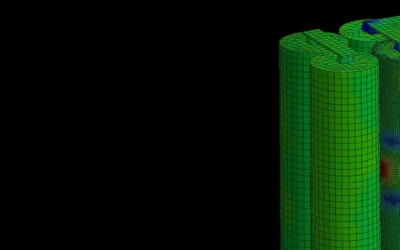

With renowned expertise in developing and manufacturing high efficiency power conversion products, Rectifier Technologies recently launched an 11kW DC Home Charger and is developing a 50kW EV charger module, both engineered to lead the transformation the e-mobility industry is facing.

Efficiency and reliability work in tandem as the DC Home Charger delivers 11kW of power in a slimline design, ideal for low-profile wall mounts or narrow spaces, such as garages, carports as well as shopping centres and office buildings. Bi-directional charging capabilities are also integrated, enabling an EV to export its energy to reduce grid dependence.

The 50kW[L2] charger module, RT22, on the other hand is suitable for all power classes of DC charging and is rated for continuous operation and high efficiency. As a scalable and future-proof solution, it enables charger manufacturers to achieve any charger power class by simply connecting RT22 modules in parallel.

Nicholas Yeoh, Director of sales at Rectifier Technologies

[1] https://www.consumerreports.org/hybrids-evs/electric-cars-101-the-answers-to-all-your-ev-questions/

[2] https://www.myev.com/research/comparisons/the-longest-range-electric-vehicles-for-2019

[4] https://fortune.com/2016/03/13/cars-parked-95-percent-of-time/

[5] https://www.greencarcongress.com/2019/07/20190709-fotw.html